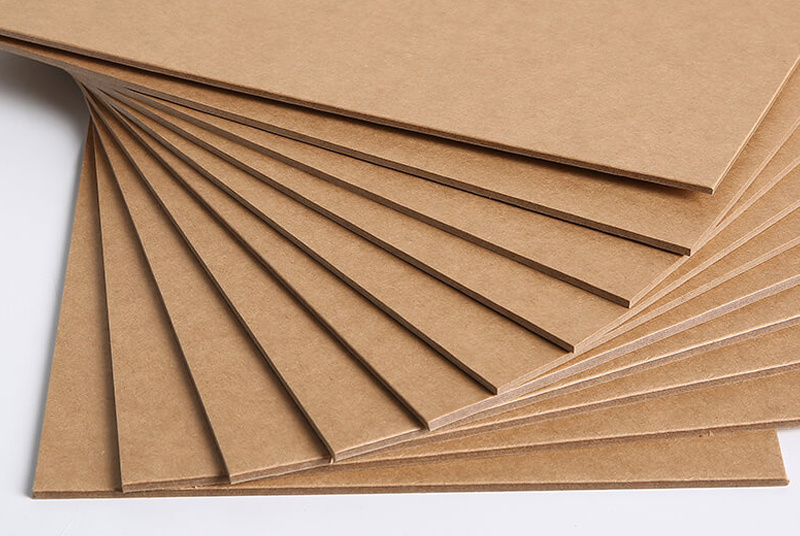

Main products

Our company is willing to cooperate sincerely with knowledgeable individuals both domestically and internationally, share benefits, strive to explore, and work together to create the future of packaging.

ABOUT DPACK

Dongguang County Dongguang Packing Machinery Co. Ltd.

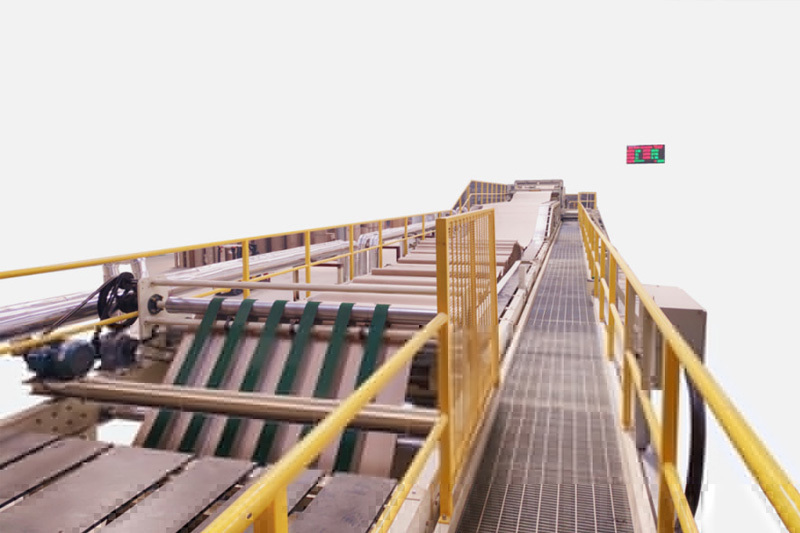

Dongguang County Dongguang Packing Machinery Co. Ltd. is a new-type joint-stock enterprise transformed from Dongguang Packaging Machinery General Factory of China National Packaging Corporation (Hebei), which has developed for more than 30 years. We’re specialized in the R&D and manufacturing of two-, three-, five- and seven-layer corrugated cardboard. Our products have been sold nationwide and exported to many countries and regions such as Europe and America, Russia, India, Middle East, Africa, and Southeast Asia. Our products are well received by users at home and abroad with high quality and gain us good reputation.

For many years, we have adhered to the tenet of “quality first and integrity-based”, and have been committed to providing users with high-quality and advanced products with excellent performance, and meeting their needs. We are looking forward to cooperating with people with breadth of vision in China and beyond to share the benefits, blaze new trails and building a bright future in the packaging industry together.

News Center

Our company is willing to cooperate sincerely with knowledgeable individuals both domestically and internationally, share benefits, strive to explore, and work together to create the future of packaging.

Main Products

We are looking forward to cooperating with people with breadth of vision in China and beyond to share the benefits, blaze new trails and building a bright future in the packaging industry together.

We are looking forward to cooperating with people with breadth of vision in China and beyond to share the benefits, blaze new trails and building a bright future in the packaging industry together.

we have adhered to the tenet of “quality first and integrity-based”, and have been committed to providing users with high-quality and advanced products with excellent performance, and meeting their needs.

we have adhered to the tenet of “quality first and integrity-based”, and have been committed to providing users with high-quality and advanced products with excellent performance, and meeting their needs.

we have adhered to the tenet of “quality first and integrity-based”, and have been committed to providing users with high-quality and advanced products with excellent performance, and meeting their needs.